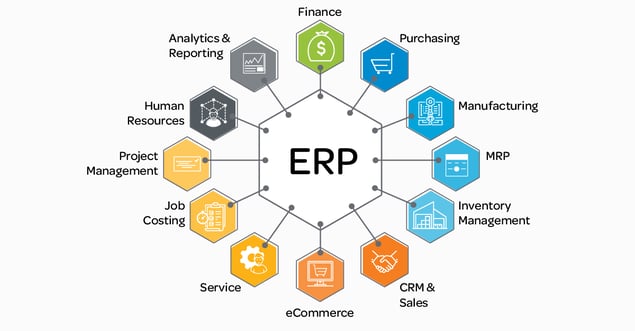

Enterprise Resource Planning (ERP) is a powerful tool. It helps businesses manage their resources. One of its key features is inventory management. Let’s dive into how ERP can improve inventory management.

What is ERP?

ERP stands for Enterprise Resource Planning. It is software that integrates core business processes. These processes include finance, HR, and inventory management.

What is Inventory Management?

Inventory management means keeping track of products. It involves ordering, storing, and using a company’s inventory. It ensures you have the right amount of stock at the right time.

Why is Inventory Management Important?

Inventory management is crucial for business success. It helps reduce costs and meet customer demands. It also prevents overstock and stockouts.

How ERP Improves Inventory Management

ERP improves inventory management in many ways. Let’s explore some key benefits:

1. Real-time Inventory Tracking

ERP systems provide real-time tracking. You can see inventory levels at any time. This helps in making quick decisions.

2. Automated Reordering

ERP can automate reordering. It calculates when stock is low. It then places orders automatically. This reduces the risk of running out of stock.

3. Centralized Data

ERP systems store all data in one place. This makes it easy to access and manage information. It improves efficiency and accuracy.

4. Improved Forecasting

ERP systems use data to predict future demand. This helps in better planning. You can avoid overstock and stockouts.

5. Cost Reduction

ERP helps reduce costs. By optimizing inventory levels, you can save money on storage. It also reduces waste and obsolescence.

6. Enhanced Reporting

ERP systems offer detailed reports. These reports help in analyzing inventory performance. You can make informed decisions based on this data.

Key Features of ERP Inventory Management

ERP systems come with many features. Here are some key features of ERP inventory management:

| Feature | Description |

|---|---|

| Inventory Tracking | Monitors stock levels in real-time. |

| Automated Reordering | Automatically places orders when stock is low. |

| Centralized Data | Stores all inventory data in one place. |

| Demand Forecasting | Predicts future inventory needs based on data. |

| Reporting and Analytics | Provides detailed reports on inventory performance. |

Steps to Implement ERP for Inventory Management

Implementing ERP requires careful planning. Here are the steps to follow:

1. Assess Your Needs

Identify your inventory management needs. This will help you choose the right ERP system.

2. Choose The Right Erp System

Select an ERP system that meets your needs. Consider factors like features, cost, and scalability.

3. Plan The Implementation

Create a detailed implementation plan. This should include timelines, resources, and responsibilities.

4. Train Your Team

Ensure your team is trained on the new system. This will help in smooth transition and effective use.

5. Monitor And Adjust

Keep an eye on the system’s performance. Make adjustments as needed to improve efficiency.

Credit: www.projectline.ca

:max_bytes(150000):strip_icc()/erp-4196982-d232fedd39e64910bc29033d4db2e9ca.png)